Honeycomb Panel

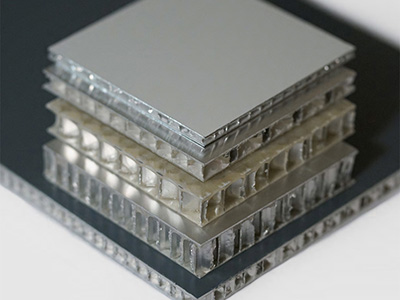

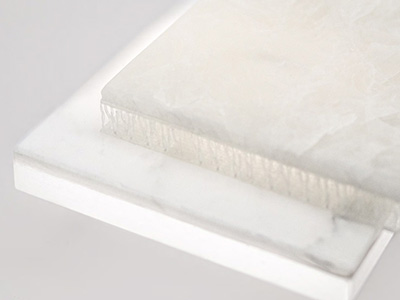

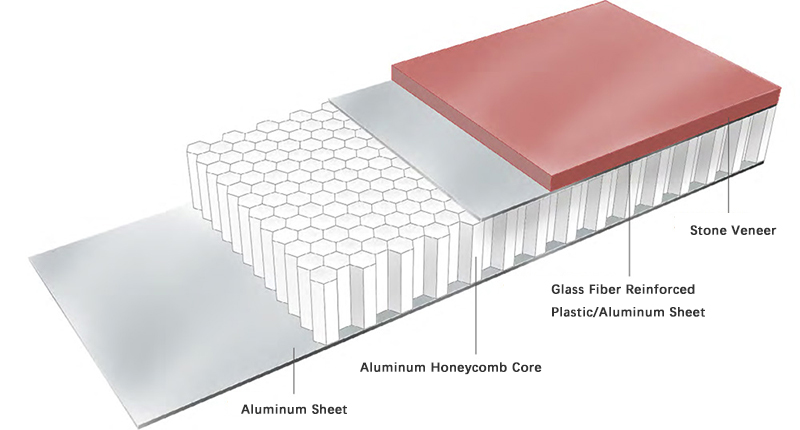

Our honeycomb panels are the perfect substitute for traditional panels, thanks to its high strength, light weight and effective mechanical properties. Traditionally, there are 5 layers to a honeycomb panel: the veneer panel, adhesive, honeycomb core, adhesive and backing. We provide a wide array of honeycomb panel surface materials, including a lightweight stone, ceramic and brick for panels with a high tensile strength such as aluminum, steel and fiberglass. The honeycomb panel is applicable for cladding systems in modern buildings, thanks to its excellent strength-to-weight ratio, excellent sound-proofing and its heat-insulating characteristics provided by the honeycomb’s geometric structure.

The honeycomb core can be designed with different densities, strength and rigidity according to actual needs and specific requirements.

The aluminum honeycomb panel is bonded with an adhesive that features a strong adhesion, excellent stability, and fire resistance that reaches international A2 levels, thus meeting strict requirements for flame retardancy in building materials. Adhesives used by us are an aviation grade epoxy resin with an exclusive formula. This adhesive has a proven performance in freeze-thaw tests and a long service life in outdoor environments.

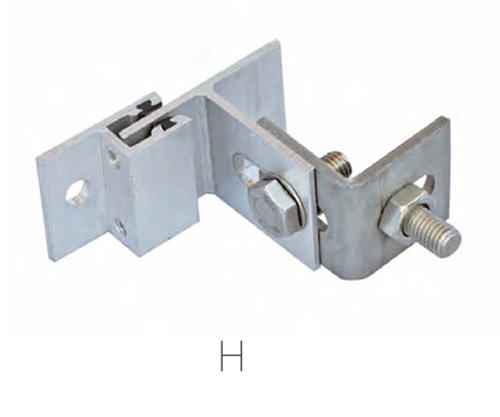

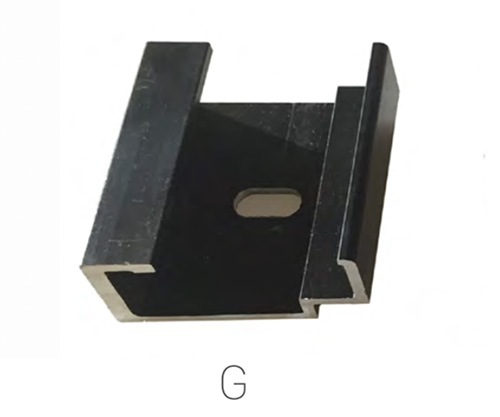

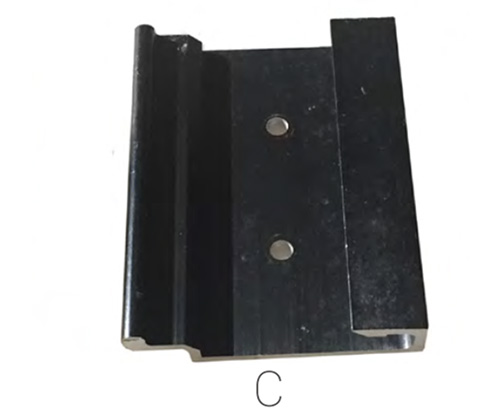

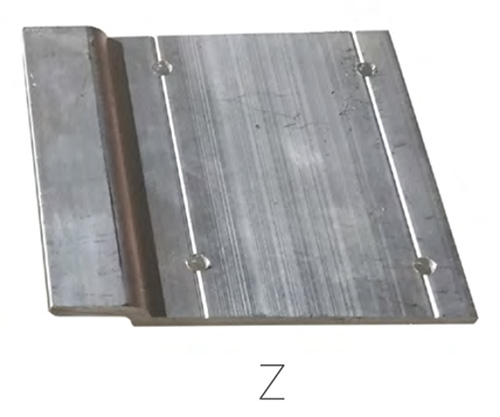

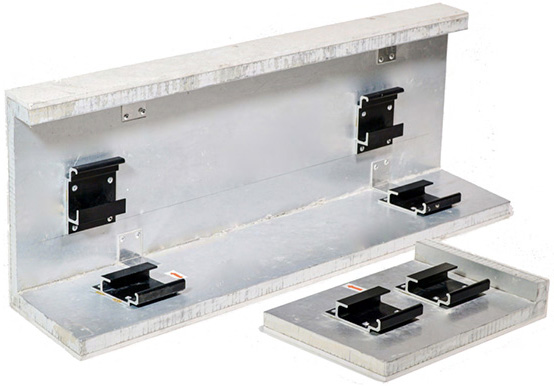

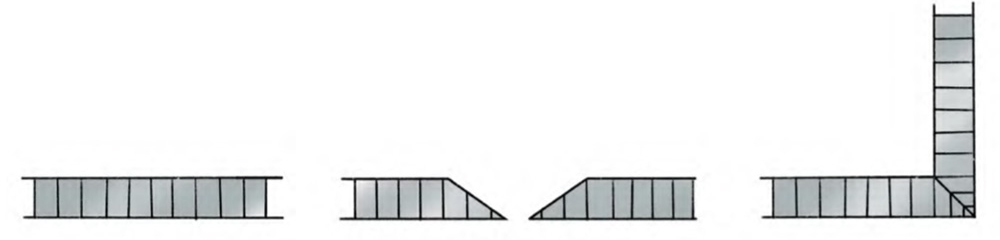

The matching interlocking clip achieves a fast, convenient on-site installation, which saves overall project costs through the improvement of project efficiency. In addition to interlocking clips for ceilings and mobile homes, there are four kinds of commonly used interlocking clips for HyCOMB panels. The interlocking clip is made of aluminum or stainless steel processed using high precision CNC equipment.

- H-type interlocking clip-suitable for indoor installation

- G-type interlocking clip-suitable for outdoor installation

- C-type interlocking clip-suitable for outdoor installation

- Z-type interlocking clip-suitable for bathroom and elevator room

The joint process for HyCOMB honeycomb panels and the special edge banding process make it easy to install and offer a smooth appearance.

Request a Quote? Feel free to contact us at any time!

click here